From our humble beginnings as a small family business to our exponential growth into a family of companies, our core values have never wavered. As Atlanta’s #1 Woman-Owned Business, “We Care” is a motto that begins with CEO Marcia Taylor and drives every employee, owner-operator, cont…

Bennett Equipped to Support Wind Energy Business Boom

Wind energy has become a huge driver of jobs and economic growth for the U.S. economy with no end in sight. The industry is expected to grow from 102,000 to 248,000 jobs in the next four years. The U.S. Department of Energy projects that wind energy will be able to supply 10% of the country’s energy by 2020, 20% by 2030 and 35% by 2050.

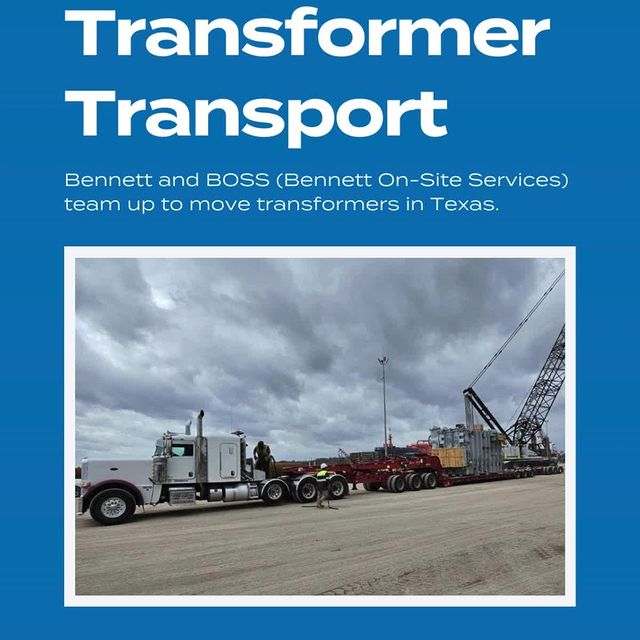

Bennett is ready to help load, transport and build hundreds of wind turbines in the coming years.